. 29 Jul 2009.,. Yeah, I’m an overachiever.

I originally thought I could fit all of my notes from ‘s class, The Amazing Dremel, into one blog post. I did not take into account how many notes I took during the workshop. In fact, my table neighbor at the workshop teased me for two days on how many notes I took. My plan is to split the information into three blog posts:. Dremel bits and what they do (hey – that’s what you’re reading now!).

Please note that this post only focuses on what the bits look like and what they do. Oh, and the bits mentioned are the only ones that we used in the workshop – we didn’t use any routing bits. That said, let’s talk bits. I think that one of the things that both attracted me and freaked me out about the Dremel was its huge buffet of accessories.

The packages are labeled by use, but it still seemed like gibberish to me. Jill created the perfect environment for overcoming my Dremel fear. You can read about my class in the following blog posts:.

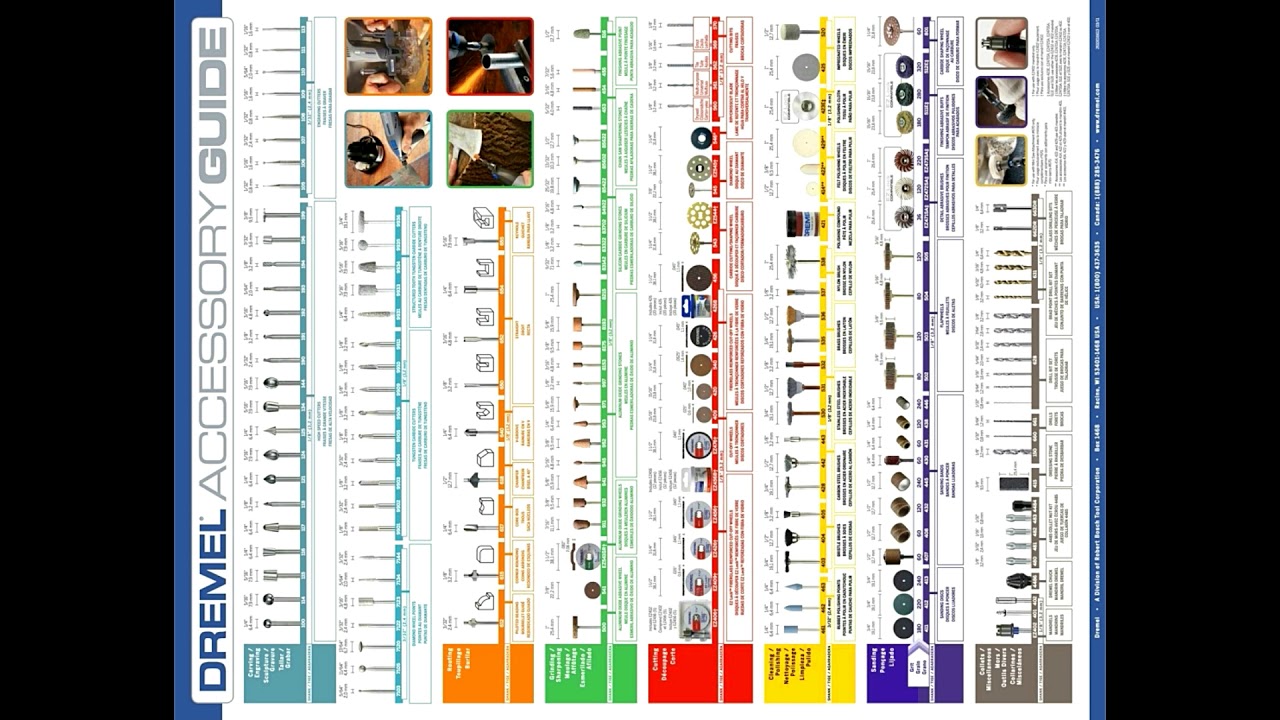

This post is in no way meant to replace the total awesomeness of taking Jill Timm’s class. I benefited so much from hearing Jill’s experiences and seeing her work in person. If I had bought a Dremel and experimented with it on my own, most likely I would have never tried it on the range of materials that we did in class. Jill recently announced that and would love to be scheduled by your group. I highly recommend the class if you have a chance to attend. The main categories of bits, according to Dremel, include the following:. Carving & Engraving.

Sanding. Cutting.

Grinding & Sharpening. Cleaning & Polishing These categories are pretty consistent among other manufacturers of rotary tool accessories, so you can often find alternatives if you shop around. Carving & Engraving I used two different types of bits that fall into the carving & engraving category – diamond bits and high speed cutters. Dremel mandrel Unscrew the tiny screw on top of the mandrel and remove one of the washers.

Slide the wheel onto the screw, then add the second washer. Attach the screw to the mandrel base and tighten. Replace the wheel it when it wears out. Grinding & Sharpening Grinding and sharpening stones are made of two basic materials: silicon carbide (green bits) and aluminum oxide (brown, orange, pink, or grey bits). You may have noticed that some of my grinding stones are oddly-shaped.

This is because the stones wear out with use. You can reshape your grinding stones using a. Polishing compound To use a polishing felt, you have to attach it a mandrel (different from the cutting wheel mandrel).

The felt has a tiny hole in the center of it – you screw the mandrel into the hole to attach it. Felt polishing wheels and cones can be used with the following materials:. Aluminum. Ceramic tile. Glass.

Mirror For further reference, you can check out Dremel’s website for information on all of their. Even better though, is this very sexy poster:. We got one of these posters from Jill in our workshop packet. I can’t decide if I want to hang it in my studio. Hi, Thanks for this great resource; there are a lot of different bits and it’s always confusing to chose the right one. Another issue I’m often facing is how to chose the right speed for each bit/material. I already noticed you could easily set a wood piece on fire if you use a too high speed; Also when cutting metal, it’s easy for the bit to start glowing red which is probably not a good thing.

Any idea where this information can be found? (or a rule of thumb to avoid destroying the bit and/or the work piece?) Thanks 🙂. I’ve been searching now for a week to find what I’m looking for, eBay, Amazon, drill retailers, hobby shops, ‘Marts – you name it I’ve searched! OK, I need drill bits to fit a Dremel but with a cutting edge of 4mm and 4.5mm. So what I need are drill bits with a reduced shank, i.e.

Dremel Accessory Guide Pdf

I need to drill 4mm and 4.5mm holes 1/2″ deep down the center of round plastic billets 1″ long x 5/8″ dia. Using dremel fitted to my workstation drill press. I would appreciate any input/info from anyone. Elissa- Your welcome for the kind comment. Fanuc a16b-1212-0871 manual. Since I posted that I added a new toy, a Dremel 3000 (the first actual Dremel I have ever owned, previously owning a cordless Black and Decker Wizard and a the cheap single speed rotary tool from Harbor Freight, along with the Chicago Electric Variable Speed Rotary Tool from Harbor Freight that I mentioned in my post above). Haven’t actually used the Dremel 3000 yet, instead still using the Chicago Electric Rotary Tool, as it is the one currently set up hanging form the stand with the Flex Shaft attached since I have been engraving some river rocks so that they are runestones for a friend who is into stuff like tarot card readings, tea leave readings, etc figured the runestones would be perfect since their mothers side is of Nordic decent (fathers side is Scottish, so there is also the possibility some of the ancestors on that side may have also used runes). I do know one thing if you have the Dremel Dust Blower (or even a 3rd party/Chinese knock off of it) you need to be real careful, I have found that out the hard way, it is very easy to brush a finger against it when it is spinning, and if you do you will burn yourself, luckily the friction burns i got on two of my fingers aren’t that bad, though one did blister up:(.

Dremel 220 Piece Accessory Kit

Other then having to be even more careful the Dust Blower is a nice little attachment, it does act as a replacement collet nut so you wont be able to use it if you use a Keyless Chuck (also a nice attachement/accessory to have), that does blow the dust, wood shavings, etc off of what you are working on so you have a clearer view of the surface when working. As mentioned above and in my other post the Keyless Chuck is also a nice addition, it allows you to use accessories (the bits) with different sized shanks without having to take the collet nut off and put in a different collet, so you can easily go from a 1/8″ shanked bit to say a 1/16″ bit, back to another 1/8″ bit fairly quickly (compared to having to remove the collet nut each time). Now the Keyless Chuck might not work with some of the attachments such such as the Dremel A679-02 Lawnmower, Gardening tool/Chainsaw Sharpening kit as the Keyless chuck sits to far forward on the Rotary Tools shaft and the grinding stone(s) you use for sharpening wont line up with the attachments sharpening guide (or in the case of the garden tool sharpener attachment the grinding stone wont fit if used with a Keyless Chuck). Now thats not so say I dont recommend the Keyless Chuck, because I do, I have 2 of them (one for the Chicago Electric Rotary Tool that fits its larger diameter shaft, and an actual Dremel one for my Dremel 3000) I primarily purchased them for use since I have a bunch of diamond tipped engraving bits that are 3/32″ shanks along with all the 1/8″ shanked bits that came with both the rotary tools and in various accessory sets I purchased (such as the 228pcs set same as/similar to the one you got from Jill Timms workshop). One last item that I can think of right now that I would suggest for your rotary tool is the Dremel A550 Shield if you plan on doing a lot of cutting with the abrasive cutting wheels (and even the fiberglass reinforced cutting wheels), metal grinding, or using the brass or steel bristled brushes.

The shield screws onto the tool where the collar cap is and then can be rotated around so that the shield is between you and the bit. Doing this if the cutting wheel breaks, sparks fly or bristles break of when using the rotary tool the shield will deflect any broken cutting wheel bits, the sparks from grinding, broken bristles, even debris from what you are working on away from you.NOTE. This item isn’t a replacement for eye protection, but is to be used in conjunction with the proper eye wear. Sorry if this is a long winded post, hoping that someone can find some of the information in it useful.

I have some rough gemstones that I need to shape smooth and polish. Which grinding stone do I use first two grind and shape the stone? Which grinding stone do I use to smooth the rough part of the stone light on top of the stone and on the side of the stone. Do I use the pink ones first when smoothing the stone and then use the orange ones to smooth it even more or do I use the sanding drums to make the final smoothing of the stone and which bit would I use if I want to smooth a scratch in the stone.

Once I have smooth the stone I guess that is when I use the felt wheels with polishing wax to make this stone shine. I bought dog SE Rotary tool accessory kit 228 piece Will this set do all the things I need to do with the Ruffstone to turn it in to A nice polished gemstone. This is all very new to me so I would really appreciate if someone can help me with the step-by-step if it’s not too much of a problem or if you know of a video that shows me the step-by-step. Thank you and I hope to hear from you soon.